Maintenance Tips for an Expansion Tank

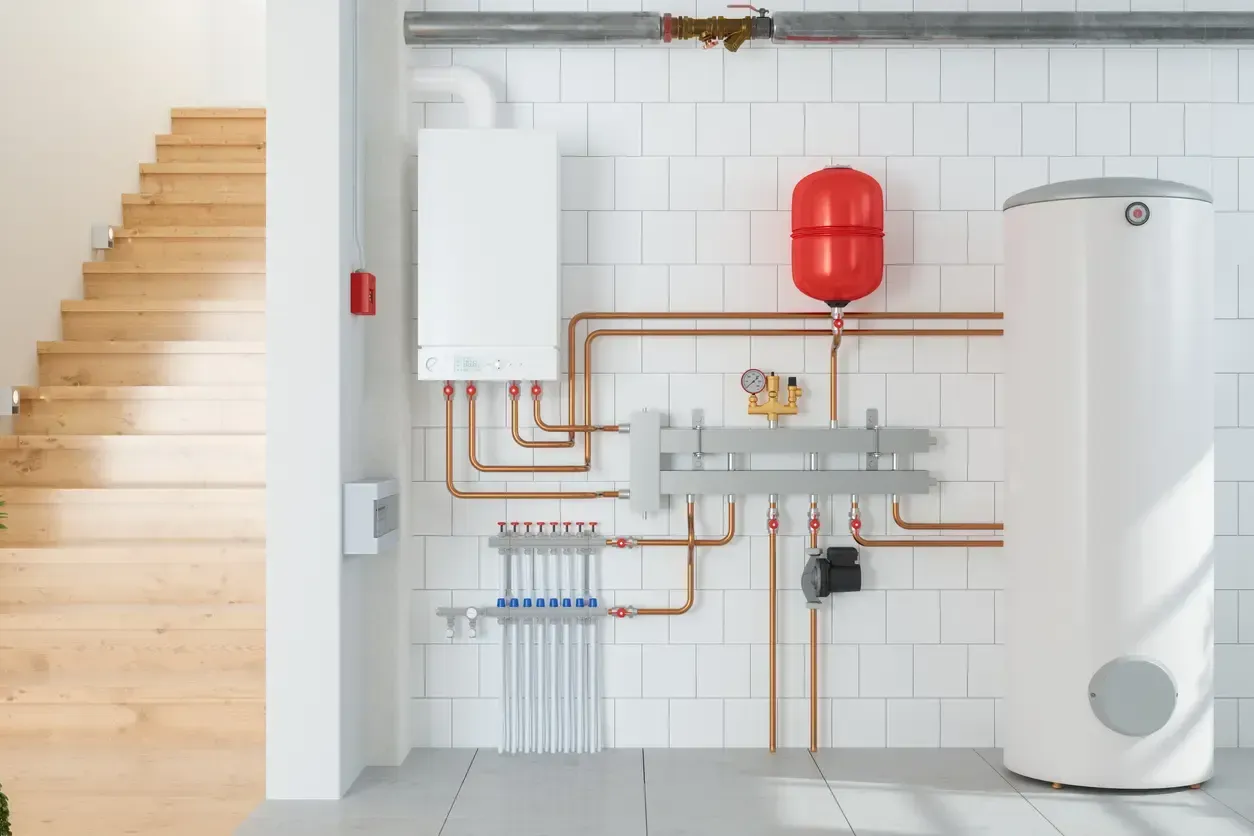

It’s easy to overlook your expansion tank—until something goes wrong. Nestled quietly above or beside your boiler or water heater, it might not seem like the most vital part of your system. But in truth, the expansion tank plays a crucial role in keeping pressure levels safe and your entire heating or plumbing system running smoothly. When it’s neglected, you might end up with problems that range from annoying to downright dangerous.

This guide is here to demystify your expansion tank, walk you through common issues, and share expert-level maintenance tips that will save you from expensive repairs down the road. Whether you're a seasoned DIYer or just someone who wants to avoid a plumbing emergency, these tips will help you keep that often-forgotten component in excellent shape.

5 Ways of Removing Hard Water Stains From Your Shower Glass

What Does an Expansion Tank Actually Do?

Before we get into maintenance, it helps to understand the purpose of the expansion tank. Simply put, this tank is a safety device. In a closed-loop heating system or domestic hot water system, as water heats up, it expands. This increased volume creates pressure, and without anywhere to go, that pressure could damage your pipes, boiler, or water heater.

That’s where the expansion tank comes in. It absorbs the extra pressure, like a shock absorber for your plumbing. Inside the tank, there's a rubber diaphragm separating the water from a pocket of compressed air. When pressure rises, water pushes against this diaphragm and displaces the air, relieving the strain on the system. When the system cools, the air pushes back, restoring balance.

Without a properly working expansion tank, pressure buildup can trip relief valves, shorten the life of your system, and even cause leaks or bursts.

Common Causes of Expansion Tank Issues

Over time, like any mechanical component, an expansion tank can wear out or malfunction. One of the most common issues is a loss of air pressure in the air chamber. If the internal diaphragm ruptures or leaks, water can fill the entire tank, leaving no room for expansion. The result? A system that constantly relieves pressure through the relief valve—sometimes even leaking or flooding.

Other issues include corrosion, which weakens the tank structure, and improper sizing, which leads to performance problems even if the tank is working as designed. External wear and tear, poor water quality, or incorrect installation can all contribute to these failures. That’s why proactive maintenance isn’t just helpful—it’s necessary.

Step-by-Step Guide to Expansion Tank Maintenance

Regular maintenance doesn’t require a plumbing degree, but it does require consistency and attention to detail. Here's how to properly check and maintain your expansion tank to avoid surprises.

Step 1: Turn Off Power and Water Supply

Safety first. If you're dealing with a hot water or boiler system, turn off the system and allow it to cool before doing any checks. Shut off the water supply leading into the expansion tank so you’re not dealing with pressure while working.

Step 2: Check the Air Pressure

Use a standard tire pressure gauge to check the air pressure at the Schrader valve (usually located on top or bottom of the tank). For most residential systems, the pressure should be around 12 to 15 PSI, but always verify your system's specific needs. If the pressure is too low, use a bicycle pump or air compressor to adjust it accordingly. Just don’t overinflate—too much pressure can render the tank ineffective.

Step 3: Tap Test for Waterlogging

One simple method to check whether the tank is waterlogged is to give it a light tap. If it sounds hollow at the top and dense at the bottom, it’s working as intended. If it sounds solid all over, it’s likely full of water—meaning the internal diaphragm has failed, and it may need replacement.

Step 4: Inspect for Leaks or Corrosion

Look closely at the fittings, seams, and body of the tank for any rust, mineral buildup, or visible leaks. Even small drips can signal the start of something more serious. Clean off any residue so you can monitor changes over time.

Step 5: Drain and Re-Pressurize (If Needed)

If you suspect waterlogging but the tank isn’t visibly damaged, you might try draining the water out of the system to re-pressurize the tank. This process can be a bit technical and may involve isolating the tank, draining the water, and inflating the air side back to the recommended pressure before reintroducing water. If you're unsure about this, it's best left to a plumber.

Risks of Ignoring Expansion Tank Maintenance

Neglecting your expansion tank can lead to a chain reaction of plumbing problems. When a tank fails, the excess pressure will force safety valves to open frequently, leading to water waste, fluctuating pressure, and possibly system failure. Over time, your water heater or boiler might wear out prematurely or develop leaks, which are far more expensive to fix or replace than a simple tank tune-up.

In extreme cases, high pressure could even cause pipe bursts—especially in older plumbing systems not built to withstand such stress. It's not just about comfort and efficiency—it's about safety.

Expert Recommendations: What the Pros Want You to Know

Plumbers and heating professionals agree on one thing: expansion tanks should be inspected at least once a year. If you’re in an area with hard water, consider inspecting even more frequently due to increased wear from mineral buildup.

Professionals also recommend replacing the tank every 5 to 10 years, even if it appears to be working fine. That’s because internal issues can develop long before they show visible signs. Using a tank that matches the size and pressure of your system is also critical—an undersized tank will fail faster and cause inefficiencies.

If you're installing a new system or upgrading your water heater, ask your technician about the expansion tank options available, including ones with built-in pressure gauges or corrosion-resistant linings for longer life.

Preventive Measures to Avoid Future Headaches

The key to long-lasting performance is routine care and vigilance. Keep a maintenance calendar and set reminders to check your expansion tank every six months. Make it part of your seasonal home checkup—alongside changing HVAC filters or checking smoke alarms.

Know your system’s normal operating pressure and temperature. That way, any sudden changes can be caught early. If you hear strange noises, notice frequent leaks from the relief valve, or see rust around your water heater, check the tank right away.

If you live in a cold climate, make sure your expansion tank is protected from freezing temperatures, which can affect air pressure and even cause rupture. Insulating the pipes and surrounding area can help maintain consistent performance.

Wrapping It Up: A Little Maintenance Goes a Long Way

Your expansion tank may be out of sight, but it should never be out of mind. It's one of the unsung heroes of your heating and plumbing system—quietly doing its job until, one day, it doesn't. But with just a bit of attention, you can keep it in excellent shape, avoid pressure-related disasters, and extend the life of your entire system.

So take a few minutes today to check the pressure, listen for warning signs, and make a mental note to give your tank the care it deserves. Because a well-maintained expansion tank doesn’t just protect your plumbing—it gives you peace of mind.